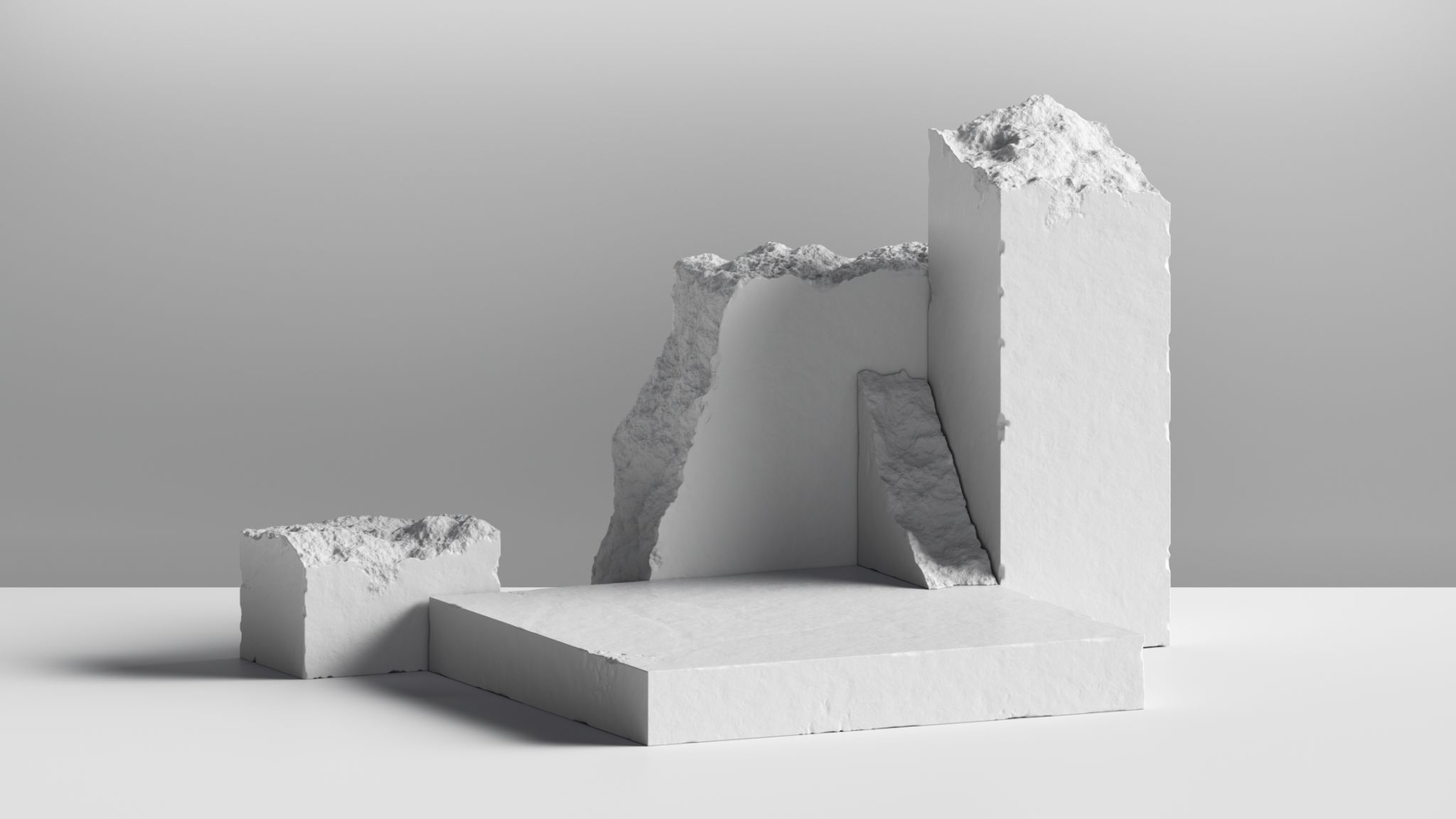

Behind the Scenes: A Journey Through the Stone Production Process

The Initial Stages of Stone Extraction

The journey of a stone from quarry to market is both fascinating and intricate. It begins with the careful selection of a quarry site, where geologists analyze the composition and quality of the stone. This initial stage is crucial, as it determines the overall feasibility and sustainability of the quarrying project. Once a suitable site is identified, the team prepares the area for extraction, ensuring minimal environmental impact.

Once the preliminary site work is completed, the extraction process begins. Advanced machinery is employed to cut and extract large blocks of stone. The use of modern technology ensures precision and efficiency, reducing waste and enhancing the quality of the extracted stone. This stage requires skilled operators who can manage the machinery and oversee the safety protocols.

From Rough Blocks to Refined Slabs

After extraction, the massive stone blocks are transported to processing facilities. Here, they undergo a transformation from raw blocks to refined slabs. The first step involves cutting the blocks into manageable sizes using diamond wire saws or gang saws. These tools are essential for achieving smooth cuts that maintain the integrity of the stone.

The slabs are then polished to reveal the natural beauty of the stone. Polishing enhances the color, texture, and shine, bringing out unique patterns that make each slab one-of-a-kind. This process requires meticulous attention to detail, as even minor imperfections can affect the slab's overall appearance.

Quality Control and Inspection

Quality control is a critical component of the stone production process. Each slab undergoes thorough inspection to ensure it meets industry standards. Inspectors look for cracks, blemishes, and other imperfections that could compromise structural integrity or aesthetic appeal. Only slabs that pass this rigorous inspection move on to the next phase.

During this stage, any necessary repairs or adjustments are made to guarantee the final product is flawless. This commitment to quality ensures that customers receive only the best materials for their projects.

Customization and Finishing Touches

Once the slabs have passed inspection, customization begins. This step allows clients to specify dimensions, finishes, and edge profiles according to their project needs. Whether for flooring, countertops, or architectural features, customization ensures that each piece fits seamlessly into its intended design.

Finishing touches can include specialized treatments like honed or textured surfaces, which add unique character to the stone. These enhancements offer both aesthetic appeal and functional benefits, such as increased slip resistance or reduced glare.

Packaging and Distribution

The final stage involves packaging and distribution. The slabs are carefully packaged to prevent damage during transportation. This often includes protective materials like foam or wooden crates to cushion the stone and keep it secure.

Efficient logistics ensure that the finished products reach their destination in pristine condition. Distribution networks span globally, with stones shipped to various markets where they are used in residential, commercial, and industrial projects.

The Enduring Appeal of Natural Stone

The journey from quarry to market highlights the artistry and precision involved in stone production. Each stage reflects a commitment to quality and sustainability, ensuring that natural stone remains a sought-after material in construction and design.

The enduring appeal of natural stone lies in its beauty, durability, and versatility. As you walk through a building adorned with stone features, remember the intricate process that brought these stunning elements from nature's depths to your surroundings.