The Art of 3D Prototyping in the Stone Industry: From Concept to Creation

Introduction to 3D Prototyping in the Stone Industry

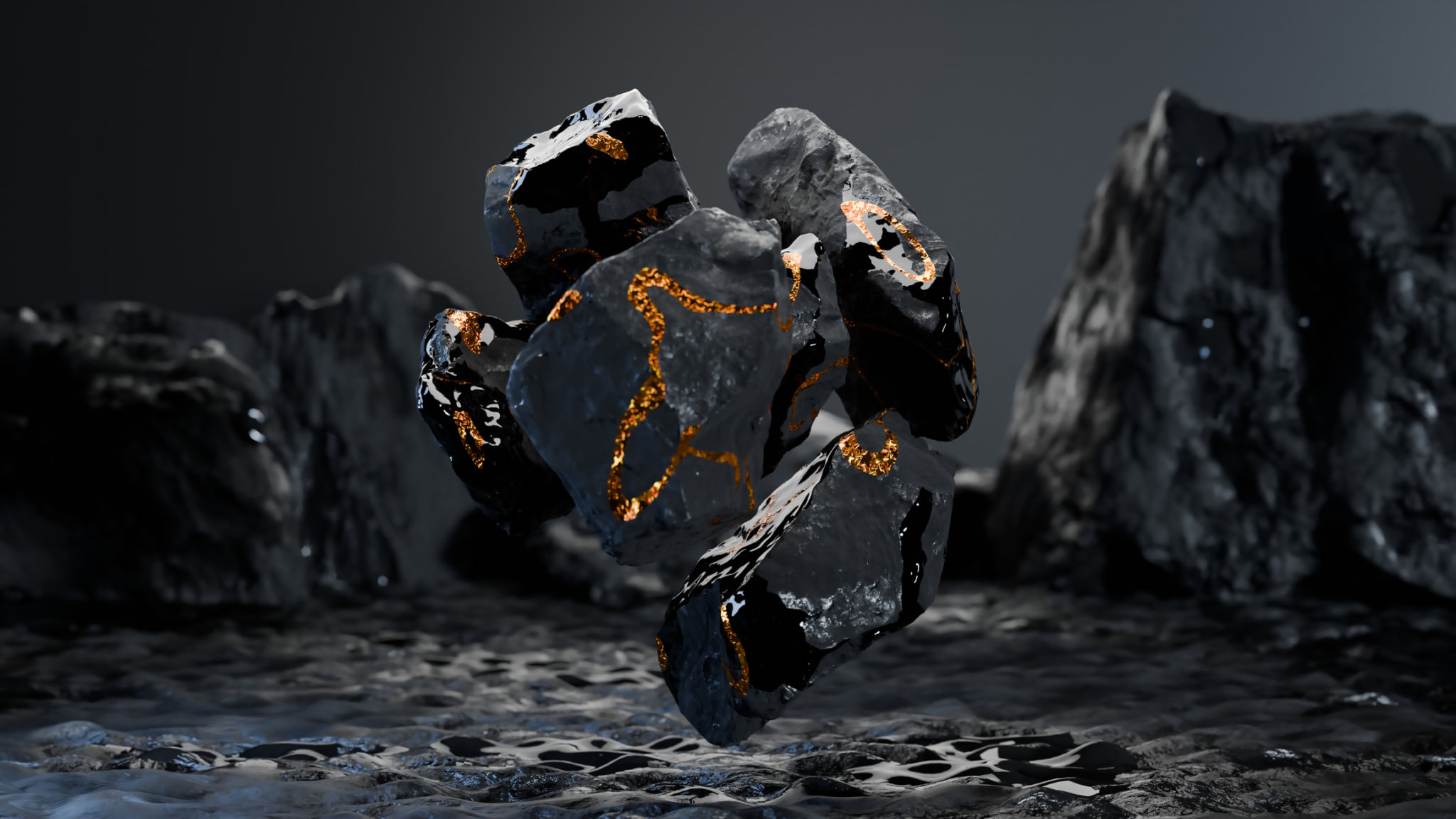

The stone industry, known for its timeless beauty and durability, has embraced modern technology to enhance its creative process. One of the most significant advancements is the use of 3D prototyping. This cutting-edge technique allows designers and architects to bring their concepts to life with precision and efficiency. By utilizing 3D prototyping, the stone industry can now create intricate designs that were once thought impossible.

3D prototyping has revolutionized the way projects are conceptualized and executed. It bridges the gap between imagination and reality, providing a tangible representation of ideas. This technology not only saves time and resources but also enhances creativity, enabling artisans to explore new possibilities in stone design.

The Process of 3D Prototyping

Conceptualization

The journey of 3D prototyping begins with conceptualization. This is where designers sketch initial ideas and gather inspiration. The goal is to create a concept that aligns with the client's vision while pushing the boundaries of traditional stonework. During this phase, designers consider various factors such as texture, color, and form to develop a comprehensive design blueprint.

Digital Modeling

Once the concept is finalized, it transitions into digital modeling. Designers employ advanced software to create a virtual 3D model of the project. This step is crucial as it allows for detailed visualization and modification of the design before any physical work begins. Digital modeling ensures accuracy and provides stakeholders with a clear understanding of the final product.

From Virtual to Physical: Creating the Prototype

3D Printing

After the digital model is perfected, it's time to bring it into the physical world through 3D printing. This process involves using specialized printers that build the design layer by layer, often using materials like resin or powder-based composites. 3D printing provides a precise and scalable prototype that can be evaluated for form and function.

Refinement and Testing

With the prototype in hand, artisans can assess the design's practicality and aesthetics. This stage may involve refining certain elements or making adjustments to improve the final product. Testing ensures that the design meets all structural requirements and adheres to the client's specifications.

Benefits of 3D Prototyping in Stone Design

The adoption of 3D prototyping in the stone industry offers numerous benefits:

- Increased Precision: Enables detailed and accurate designs that were previously unattainable.

- Cost Efficiency: Reduces material waste and minimizes errors during production.

- Time Savings: Accelerates project timelines by streamlining the design process.

- Enhanced Creativity: Encourages innovation by allowing complex and intricate designs.

The Future of 3D Prototyping in the Stone Industry

The future of 3D prototyping in stone design is bright, with endless possibilities on the horizon. As technology continues to evolve, we can expect even more sophisticated tools and techniques that will further transform the industry. The integration of artificial intelligence and machine learning may offer personalized design solutions, while advancements in materials could introduce new textures and finishes.

Ultimately, 3D prototyping is not just a technological advancement; it is an art form that harmonizes creativity with precision. As the stone industry continues to innovate, 3D prototyping will remain at the forefront, shaping the landscapes of tomorrow.